Which materials should you choose for your POP displays?

1200 words

#marketing #POP #display #branding

May 2025

Wood, metal,Wood, metal, plastic, glass, leather — each material carries a unique emotional and functional weight, and every combination tells a story that shapes the brand experience.

Wood gives off a feeling of authenticity and warmth. Metal brings a modern and strong look — though it can sometimes become invisible. Plastic lets you go bold and creative, while glass adds a touch of elegance. Even the smallest material accents, textures, or contrasts can send a strong, subtle message.

Of course, image is just one side of the story. The material you choose has to perform too: how long it lasts, how much weight it can handle, how easy it is to put together, what it costs — and whether it meets regulations.

And let’s not forget: sustainability is no longer optional. Eco-friendly design is becoming the standard. That means thinking about recyclable materials, easy disassembly, reuse — all without losing the efficiency and desirability of your display.

So, if you’re developing a POP display, think carefully about what each material brings to the combination. There’s a lot more to consider than you might think. Let’s break it down ...

Pilotes makes commercial furniture, display and merchandising solutions. We offer 100% customized point-of-purchase materials tailored to the in-store projects of brand and retail. Because we care about the climate and environment, we analyze the lifecycle of each project to avoid, reduce, and offset its impact 🌍🌿

Do you have a project planned? Contact us and let’s bring your vision to life together!

Flex your creative muscles

To

succeed in the hubbub of shopping, material options allow to highlight your brand among others, and to

anchor memorable images in the minds of your customers!

To

succeed in the hubbub of shopping, material options allow to highlight your brand among others, and to

anchor memorable images in the minds of your customers!

Your display is the expression of your creative imagination. Material can deliver a desired visual experience or bring a touch of authenticity. They can convey quality, value, emotions and meaning.

Some material represents wealth, extravagance or power. Others indulgence and desire, or purity and eco-friendly. A detail of the packaging can be inspiring to add to the overall look.

A well-chosen material mix, accorded with the DNA of the brand, immerses the shopper in the product universe. Whether the product is medium, high-end or luxury, material options and colors make displays effective. These details create a coherent image to the target audience.

Cost

The general perception is that the more durable a material is the more it tends to cost – with cardboard usually the cheapest, followed by plastic, wood, and then metal. The reality is more complex, as it depends upon the function and desired lifetime, what production processes it need to go through, how easy it is to assemble, ...

When calculating expenses look first at what is needed according to the creative briefing, and not just the cost associated with the raw material.

Desired lifetime

The

key being distinctive, imaginative material options will help you to meet a number of less emotional, more

technical objectives, such as how long you need a display for, without any major repairs being necessary.

The

key being distinctive, imaginative material options will help you to meet a number of less emotional, more

technical objectives, such as how long you need a display for, without any major repairs being necessary.

Temporary or promotional retail displays, sometimes referred to as cardboard displays, are used as part of short-term events, such as weekly sales promotions. They wear down relatively quickly and are easily damaged. They are designed to present the promotion and dramatize the offer over short periods of time.

More durable materials are chosen for permanent retail display. Plastic lasts long, but does eventually fade and crack. Wood is a versatile material that can be used for either semi-permanent or permanent displays. Metal displays can last for several years and are suitable for long-term instore installations.

Desired use, strength and weight constraints of the products being presented

Always aiming to reduce material used, and hence reduce cost, material options are governed also by the

capacity of a POP display to perform the service functions for which it is designed. The weight of the

products presented should be carefully considered when developing design, structural strength, assembly

and material.

Always aiming to reduce material used, and hence reduce cost, material options are governed also by the

capacity of a POP display to perform the service functions for which it is designed. The weight of the

products presented should be carefully considered when developing design, structural strength, assembly

and material.

Where possible, provide your POP supplier with physical products to trial on prototypes. When products are on the heavier side, we leave products on the prototype for many days, to ensure it holds the weight!

Also, it is vital the shopper can confidently remove the product to purchase from a display, still in good shape, also after being replenished many times.

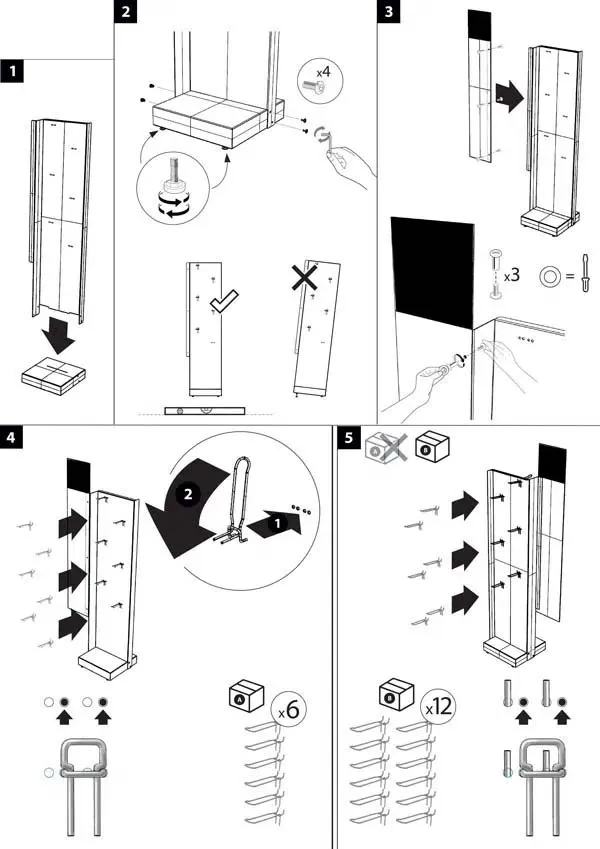

Ease of assembly

By flat-packaging display, considerable savings can be made on logistics costs (storage,

transport, ...). We provide them with clear assembly instructions.

By flat-packaging display, considerable savings can be made on logistics costs (storage,

transport, ...). We provide them with clear assembly instructions.

Is assembly performed by shop associates or experienced merchandisers? Some material is better adapted to different installation conditions.

Cardboard displays are easy to damage and require careful assembly. By comparison, plastic is harder to damage. To assemble wood properly, a certain handiness is required. Metal has its own difficulties when it comes to ease of assembly. While very hard to damage, metal displays often require more effort to assemble. Displays made of wood and metal are also quite heavy, which can increase transport costs.

Shop floor context

A window display is not to be built to resist intensive usage. However, on a sunny day some windows reach temperatures up to 100 degrees, putting stress on plastics, assemblies, prints and colors.

The conditions of the targeted shop, the intensity of usage and the expected level of surveillance, should be taking into consideration when selecting material.

The resistance of material against moist or rain could be considered for material that are to live outside.

Engineering

Not all material is suitable to be engineered for different display requirements. However, a mix can often be used together to create a solution that fits your requirements, such as a metal frame providing strength for plastic shelves and message areas.

Compliance with standards and regulations

Some shopping malls, especially in airport terminals, have developed safety strategies for material to be

used in presentations. The more important ones respond to the safety regulations for electrical

installations and to the EU-classification standard 13501-1, ranking material in 7 classes with regard to

their fire behavior.

Some shopping malls, especially in airport terminals, have developed safety strategies for material to be

used in presentations. The more important ones respond to the safety regulations for electrical

installations and to the EU-classification standard 13501-1, ranking material in 7 classes with regard to

their fire behavior.

Eco-design and end-of-life

Although it does not compromise in any way on commercial effectiveness nor desirability of the initiatives, eco-design aims to minimize environmental impact.

The effort of the point-of-purchase marketing industry has led to a number of operational recommendations for eco-design of POP display:

- Reduce the quantity of material for the same efficiency

- Opt for recycled and recyclable material

- Consider environmental impacts of material

- Take into account shelf life extension and repair

- Include dismantling instructions to facilitate sorting and recycling

- Share services for recovery of retail displays

What material is used in permanent POP display ?

From the early stage, your POP producer will guide you through the material selection. These are the most used materials for permanent POP display:

All types of metals, known for their toughness and durability, are used to create solid, sometimes invisible, structures. Epoxy finishing, available in different textures, are used to protect and beautify these parts.

PMMA, PS, PC, ABS, PE, PET, etc, are synthetic materials with different characteristics of resistance, strength and transparency. They come in all types of finish: colorless, translucid, diffusing, frosted, mat, shiny or satin, … to mention just a few.

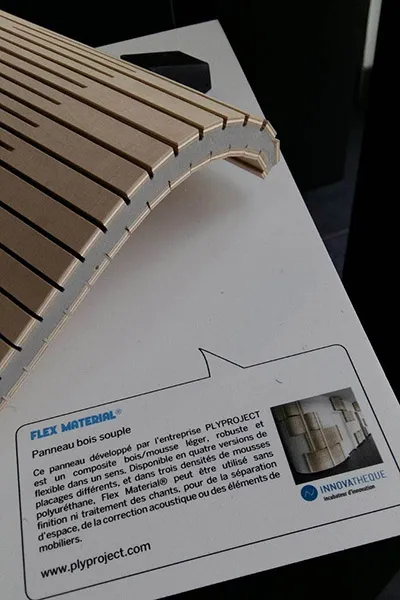

Wood is used for its solidity but also for its luxury and warm appearance. It can be tainted, varnished or coated with a décor layer, such as foil, melamine, laminate or veneer.

If you have a specific need or if you want a POP with material meeting all your requirements, reach out to set up a free consultation. We will find the best solution for you.