Know the process and times to avoid surprises:

How we make the ideal POP display for your brand

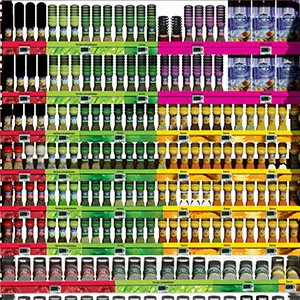

A point of purchase or point of sales display is by definition a contextual solution with a clear goal: make brands and products shine in shops. This instore communication must therefore be impactful, the main advantage of a unique, well-designed material

If it stands out chances are consumers are going to head over and take a closer look. Also, the aesthetics and presentation must be adapted to the product, brand and its target audience.

In order to benefit from the advantages of each phase, bringing a custom display solution from idea to

practical reality can be a journey divided into five crucial steps: briefing, creation, industrial

design, prototyping to industrial production.

In

this article, we explain the workflows to develop a POP material that successfully meets your commercial

and communication objectives.

In

this article, we explain the workflows to develop a POP material that successfully meets your commercial

and communication objectives.

Depending on complexity, you can expect a process of on average three to four months before installation of a permanent sales display on the shop floor.

Pilotes specializes in the design of commercial furniture, display and merchandising solutions. We offer 100% customized point-of-purchase materials tailored to the in-store projects of brand and retail. Because we care about the climate and environment, we analyze the lifecycle of each project to avoid, reduce, and offset its impact 🌍🌿

Do you have a project planned? Contact us and let’s bring your vision to life together!

1. Creative briefing (and analysis)

A

point of sale expert who knows how to listen and understands you will provide the best solutions.

A

point of sale expert who knows how to listen and understands you will provide the best solutions.

Your activity, the benefits of your product, the distinction between your product and competing offers, your brand positioning, your target audience, a particular problem to solve, changed context ... on the basis of these insights, we can identify the solutions that increase the value of your product on the shop floor.

This stage is crucial as it lays the foundation for all the other phases. It can be formalized by drawing up a creative brief, the list of expectations and needs of all stakeholders (marketing, sales, procurement, logistics, ...).

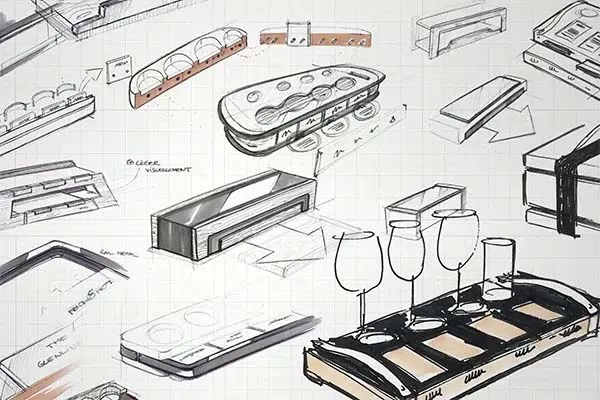

2. Ideation and creation

The ideation leads to the creation of appealing and impactful display solutions. After all, a POP

display is the expression of your creative imagination! How to design a successful POP material that

attracts, engages and increases sales?

The ideation leads to the creation of appealing and impactful display solutions. After all, a POP

display is the expression of your creative imagination! How to design a successful POP material that

attracts, engages and increases sales?

Extend your imagination with cutting-edge ideas, filter out the viable ones, discuss and pursuit ... this creative phase is key to come up with the feasible aesthetic elements that guide the overall development process.

Finally, we visualize the ideal POP solution and its characteristics through visual representations (sketch, rough, render, ...). Once you are satisfied with the creation, we move on to the next stage. With these, we test how a creation is visually experienced.

3. Industrial design

You already see your point of sale solution come to life, but now you want to research technical

feasibility and costs? Don't worry! All the gathered information is processed into an industrial design.

You already see your point of sale solution come to life, but now you want to research technical

feasibility and costs? Don't worry! All the gathered information is processed into an industrial design.

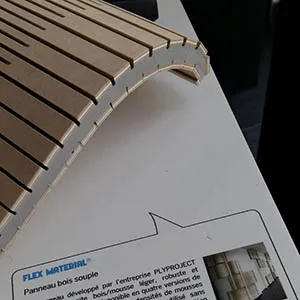

We draw the 3 dimensions of all the components on CAD software (computer-aided design). Adapted and ingenious production solutions, innovative and impactful materials... throughout the process we remain vigilant about the creation and all functional aspects. A design is only finished when we have described in detail for each part which materials and which finish are required for its production. Technical plans, outlines of printed surfaces, list of parts, assemblies, packaging, costs, delivery times, the environmental impact of the materials, ... they all constitute the production file.

4. Prototyping and validation

A prototype is the materialization of a promising idea. We make it according to its design, featuring

all technical and functional attributes.

A prototype is the materialization of a promising idea. We make it according to its design, featuring

all technical and functional attributes.

Making it tangible makes it easier to evaluate the concept prior to full scale production: aesthetics, shapes and colours, print, assemblies, robustness, stability, finish and quality, interaction with the presented articles, etc.

Even at this stage we sometimes come to new insights and improvements. The production file is corrected with your suggestions and feedback before validating, which is the bridge to production.

5. Manufacturing

Quality production and respect for agreed times result from all previous preparations.

Quality production and respect for agreed times result from all previous preparations.

As a builder of multi-material POP solutions, we offer a modern machine park with unlimited possibilities for processing metal, plastic, wood, glass, etc.

We organize the production process, we produce a first series model of each part and check the conformity, we validate the progress and monitor planning and quality, we organize the assembly, ...

A display material is as successful as the quality of installation on the shop floor. These lasts steps, logistics and installation, must also be anticipated!

Finally, we carry out an evaluation to continuously improve our performance.

Have the advantages of POP material aroused your interest? Reach out today, we will gladly discuss the possibilities for your product.